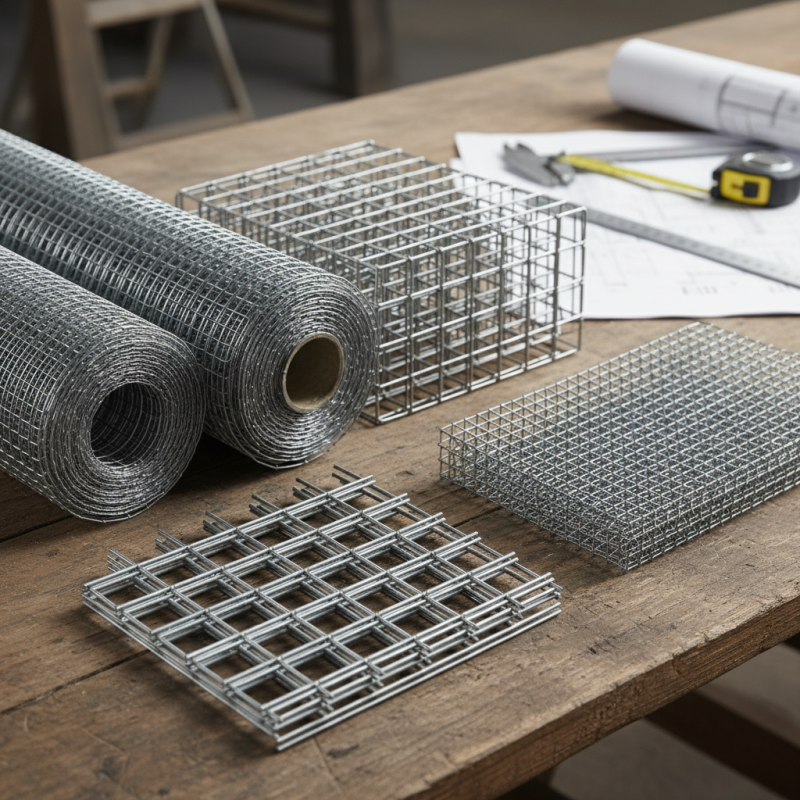

How to Choose the Right Welded Wire Mesh for Your Project?

When selecting welded wire mesh for your project, it’s crucial to understand both its applications and specifications. The global welded wire mesh market is projected to grow steadily, reaching a value of approximately $5 billion by 2026, indicating its importance in various industries. This versatile material serves a myriad of purposes, from construction to livestock fencing. However, made wrong choices can result in project delays.

welded wire mesh comes in various materials and sizes, each suited for specific applications. For example, galvanized steel mesh is popular for outdoor uses due to its corrosion resistance. On the other hand, stainless steel welded wire mesh offers superior strength in demanding environments. Yet, many overlook the importance of matching the right type with project requirements. Failing to consider the mesh aperture size or wire diameter might lead to insufficient strength where it matters most.

As you navigate your selection, think critically about your project’s demands. Factors such as load-bearing capacity, environmental conditions, and budget must be weighed carefully. Ignoring these could lead to costly mistakes. Adopting a cautious approach when choosing welded wire mesh can set a solid foundation for any project.

Factors to Consider When Selecting Welded Wire Mesh

Choosing the right welded wire mesh is crucial for any construction or landscaping project. The selection process can be overwhelming. Key factors to consider include wire diameter, mesh size, and material type. Industry reports suggest that varying wire gauges can affect strength and flexibility, with common diameters ranging from 1.0 mm to 6.0 mm.

Mesh size is another critical element. Smaller openings provide more security, while larger ones may allow better airflow. A report from the Fabricated Wire Association highlights that a 1-inch by 1-inch mesh can support lighter applications, while a 2-inch by 2-inch mesh is ideal for heavier loads. It's also important to consider environmental conditions. Corrosion-resistant materials may be necessary for outdoor projects, especially in humid areas.

Moreover, the installation process should not be overlooked. A poorly installed mesh can lead to structural failures. Budget constraints also play a significant role in the selection process. High-quality materials can have higher upfront costs but save money in the long term due to durability. Choose wisely. Each decision matters.

Types of Welded Wire Mesh and Their Applications

When selecting the right welded wire mesh, understanding its types and applications is crucial. There are various types of welded wire mesh, including standard welded mesh, hexagonal wire mesh, and barbed wire mesh. Each type serves unique purposes across different industries. For instance, standard welded mesh is commonly used for fencing, while hexagonal wire mesh is favored in agriculture for animal enclosures.

According to industry reports, the demand for welded wire mesh is projected to grow by 5% annually, driven by increased construction activities.

It’s vital to consider the gauge of the wire when choosing mesh. Thicker wires offer greater strength but may be harder to work with. Conversely, finer wires are easier to handle but may not withstand heavy loads. Each project has unique requirements. Evaluating the specific needs of your project can prevent costly errors.

Tip: Always measure the space you intend to fill before purchasing. This ensures that you choose the right size and type. Miscalculations can lead to wastage and frustration. Reflect on your previous projects. Were there any inadequacies in your choices? Adapting lessons learned can greatly enhance your future selections.

Assessing the Strength and Durability Requirements

When selecting welded wire mesh, strength and durability are key factors. Assess the specific demands of your project. Will it bear heavy loads? Or will it be subjected to harsh weather conditions? These questions guide your choice.

Different wire gauges offer varying levels of strength. Thicker wires usually provide better support. However, they can be harder to work with. A balance is necessary. Consider the mesh's cross-sectional area as well. Larger openings may reduce durability, especially in high-stress applications.

It's also important to think about coating options. Zinc coatings can enhance corrosion resistance. Yet, they are not always foolproof. Look for potential weaknesses in design that might lead to fail over time. Each project is unique, and careful consideration can lead to better outcomes. It's crucial to weigh all these factors before making a decision.

Understanding Wire Gauge and Mesh Size Implications

When selecting welded wire mesh, understanding the implications of wire gauge and mesh size is crucial. The wire gauge indicates the thickness of the wires used. A lower gauge number means thicker wire, which increases strength but can limit flexibility. For instance, a 10-gauge wire is stronger than a 14-gauge wire. If your project involves heavy loads, opt for a lower gauge.

Mesh size refers to the distance between the wires. Smaller openings provide more support but can restrict airflow. This could be vital for agricultural applications, where airflow affects plant growth. If you’re using the mesh for fencing, consider how much visibility you want. Sometimes, a balance between strength and openness is necessary.

Tip: Always test a small section of the wire mesh before committing to a larger purchase. This can help you understand how the mesh behaves under load.

It’s essential to remember that not every project requires heavy-duty mesh. Sometimes, a lighter option is more suitable. Reflect on your specific needs before making a choice. Are you prioritizing durability or cost-effectiveness? Each project is unique and demands thoughtful consideration.

How to Choose the Right Welded Wire Mesh for Your Project? - Understanding Wire Gauge and Mesh Size Implications

| Wire Gauge | Mesh Size (inches) | Opening Size (inches) | Material | Common Applications |

|---|---|---|---|---|

| 14 | 2 x 4 | 1.75 | Galvanized Steel | Fencing, Animal Enclosures |

| 16 | 1 x 1 | 0.75 | Stainless Steel | Construction, Support Grids |

| 18 | 1/2 x 1 | 0.5 | PVC Coated | Gardening, Animal Pens |

| 12 | 4 x 4 | 3.5 | Electro Galvanized | Industrial Fencing, Security |

Cost-Benefit Analysis for Your Welded Wire Mesh Choice

When selecting welded wire mesh, cost is a pivotal factor. According to industry reports, pricing can range from $0.10 to $0.50 per square foot, depending on wire gauge and mesh size. This can significantly impact budget allocation for projects. Reviewing estimated longevity in various applications often shows that investing in higher-quality mesh can yield lower long-term maintenance costs. A delicate balance between initial expenses and ongoing durability is essential.

Tips: Always assess your project’s specific needs. Consider the environment where the mesh will be used. A harsher climate might require more robust options, which can initially cost more but save money over time.

Furthermore, labor costs associated with installation should not be overlooked. If a mesh requires frequent repairs or replacements, the cumulative expenses can outweigh the benefits of a cheaper product. An analysis from the Wire Reinforcement Institute suggests that opting for a reliable, durable option can minimize labor delays.

Remember, understanding your project's requirements will lead to the best decision. Sometimes, what appears to be the cheapest option may not serve you well in the long run. A hasty choice can lead to regrets. Prioritize quality over mere cost for lasting benefits.